Wet room

floor gully

It might sound obvious,

but a wet room shower floor needs somewhere

to drain to. This simple fact is the

starting point for planning your wet room.

It is surprising how many people overlook

this fairly basic requirement, focussing

more on appearance than functionality.

Establish where you

intend to dispose of your waste water and

how you intend to get it there. No good

realising that water won't run up hill half

way through the job, or that you haven't got

enough depth to accommodate a water trap or

pipe work!

No matter what your

installation may demand there is probably a

solution, but think about it at the

conceptual stage and you won't end up with

nasty surprises or problems.

You should also

consider what type of shower equipment you

plan to install. No good putting in a system

that throws a monsoon of water at you if the

drain can only handle a meagre flow rate.

A wet room

shower in a perfect world

Although a wet room

shower may be considered attractive for its

level access or understated simplicity,

there is plenty going on below floor level.

Whatever your drainage solution, that's

where waste water will be channelled away

for disposal. In a perfect world this is

simply a matter of running a waste pipe from

the water trap in the floor to a convenient

drain. But things aren't always so simple.

If the level of the drain into which you

plan to run is higher than the wet room

floor a pumped solution may be necessary.

Even if a fall to the drain is available you

still need to run the waste pipe. This might

mean dodging or going through joists of a

timber floor, digging or making provision

for a channel through a solid floor.

Consider how much depth you have below floor

level to achieve this.

Consider how much water

your drainage will be expected to handle.

Exceed its capabilities and you may end up

with water cascading down adjacent corridors

looking for alternative ways out!

Ensure that slopes run

towards the shower area and gully. Water

finding its way outside the designated

shower area will also look for a place to

go. Ideally this will be back towards the

shower gully, not in the opposite direction

towards a corner of the bathroom, or worse

still the hallway!

A simple bit of

forethought and you'll create a prefect

result.

Ways to

drain a wet room shower floor

There are a couple of

basic ways to drain water from a wet room.

Either by gravity (allowing the waste water

to run down a pipe with a constant fall

towards a drain or with a shower waste water

pump (lifting and pushing the waste water to

a higher level).

|

You must decide

which method of disposal you will

use as the trap in the floor is

subtly different for each.

Shown right:

A normal wet

floor waste will have a 50mm water

trap (to meet with Building Regs)

and an outlet spigot of 40 or 50mm

onto which your waste pipe will

attach. A constant fall must then be

achieved on the pipework that will

run to a convenient soil pipe or

sewer as a 'gravity' flow. |

|

|

|

Pictured left:

A 'pumped waste trap' is not

actually a trap at all. It is

usually a very shallow device that

rather resembles a small frying pan.

With this, the

'handle' of the pan is in fact a

small bore spigot onto which small

bore pipework can easily attach.

This is then connected to a remote

'self-priming' pump. |

|

While there are

one or two exceptions to the above

examples (for example, when using

something like a Sanishower pump or

a Grundfos Sololift) that will work

with the larger bore outlet spigots

you cannot swap between the two

easily. Another reason to plan

carefully. |

|

Shown right:

Another

variation is the 'waterless trap'.

A slightly

contradictory title as this device

does not have a water trap inside.

Instead, it has a membrane that

snaps open in the presence of water

and then closes when dry.

The

advantage of these would be the very

low profile extending below the

floor surface, but be careful where

you choose to use one.

Because they

do not offer a 50mm water separation

(to catch foul odours coming back

from a sewer) they do not meet

Building Regs if connecting directly

into a soil pipe or sewer. |

|

|

A waterless

trap may be used if say you are

wasting into a gully outside the

building - but not connected

directly into a sewer.

Whichever

describes your scenario, remember to

match the flow rate of the shower

equipment to the flow handling

capabilities of the wet room floor

and gully setup. |

Shape of

a wet room shower gully

In general, there are

three shapes of tiled floor gully - Linear (a

long thin slot), Round or Square.

|

|

|

Above:

A linear gully showing a single

outlet spigot. (the model shown is

for use in a screed floor. The

galvanised angle brackets allow for

fixing/levelling and hold the unit

securely during installation) |

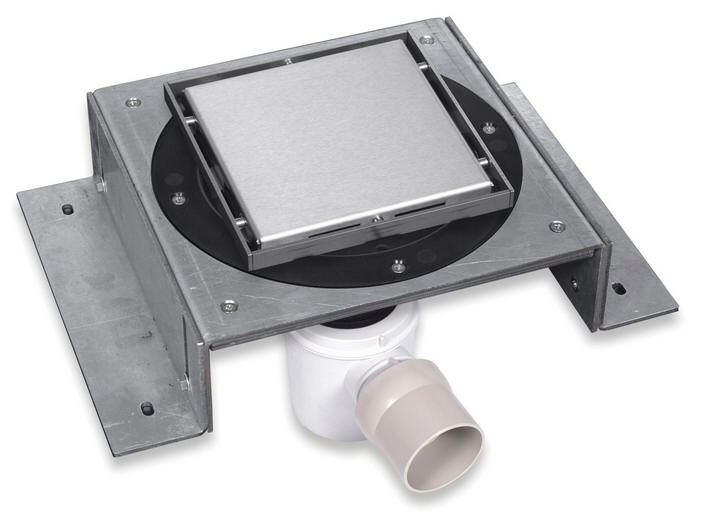

Above:

This is a square gully

assembly showing the various

components. On this model the white

trap has a horizontal outlet spigot

onto which pipework would connect. |

| |

|

|

Below: a square

gully outlet for a tiled floor

surface on a screed floor. There are

variants of this gully including a

'tile inside' gully cover. |

Shown below -

a round gully. These tend

to be exclusively used with vinyl

floor coverings such as Altro

waterproof non-slip.

The variant

shown has a 40mm outlet spigot, but

they are available for pump

connection (the frying pan) or with

a waterless trap. |

|

|

|

|

|

|

Drainage gullies with

flat edges lend themselves to a tile finish

more so than a round gully, simply because

it's easier to cut a tile straight than it

is on a curve.

While on the subject of

tiling, you should consider which of the

gullies (square or linear) will best suit

your chosen tiles.

|

A square gully

will invariably have four slopes

converging on it.

If you are

using large tiles this will require

a degree of skill when cutting all

the angles.

For this

reason, it is often considered that

small tiles are better suited to a

square gully as they are easier to

form being more forgiving.

Pictured right

is a square gully shown with the

optional 'tiled' cover. You can see

the angular cuts required to tile.

The picture

also shows how much less obtrusive

the gully is with a matching tiled

cover |

|

Linear gullies

tend to have a slope to the front and

another to the rear (there are exceptions -

especially on very large shower areas that

employ a linear drain). This can often

simplify the cutting of large tiles as there

are no difficult angles to cut. (exceptions

being larger areas with linear drains that

may still require angular tile cuts at the

corners)

Don't be fooled into

thinking that a linear drain can handle a

higher flow rate per se . Flow rate

is highly dependent on a number of factors -

capability of gully, size of waste pipe,

fall on waste pipe to drain, etc. A linear

drain with the same outlet size as a square

drain will only handle the same flow rate. A

bigger catchment area does not necessarily

equate to a better flow. It is however fair

to say that some Linear drains can be

equipped with additional outlets (the

Novellini Linear drain

for example) that can increase the flow

handling potential considerably.

a range of

square and linear gullies for a screed floor

with a tiled surface

Pumped

waste for a wet room shower floor

|

When a wet room

floor is lower than the drain into

which it will dispose of its waste

it is likely that a waste pump will

be necessary.

Depending on

available space and the distances

(vertical and horizontal) involved,

various pumps may prove suitable. It

must be said, if there is any way to

avoid using a waste pump then

consider it well before electing to

use one. Why add a mechanical device

and a significant cost to something

physics is only too happy to do for

nothing? |

|

Pictured

right: A Dry Dec 20

shower waste pump installed within a

wall behind an access panel.

The picture

shows the pump, its control box (the

brain), the two flow sensors located

in the hot and cold supply pipes to

the mixer shower equipment and a

small canister that absorbs any

shock waves created when the pump is

scavenging for water.

This is a

top end setup capable of handling

high flow rates.

Smaller

lower rated pumps are available with

examples below: |

|

Remember, evaluate what

flow the pump must handle before buying or

installing. If your pump can't keep up with

the flow rate of your shower you will end up

with a flood.

Shower waste pumps are

normally activated on a signal from flow

sensors placed in the supply pipes to the

shower equipment. Mixer showers have two

sensors (one in the hot supply, one in the

cold supply). Electric showers, having only

a cold water supply only have one sensor.

The more sophisticated

the pump and the higher the flow handling

capability the more expensive the unit will

be. For more detail please don't hesitate to

call.

To Conclude

Be mindful of a few

simple things when planning and installing

and all will be well. Remember what goes in

(or on) must go out (down the drain).

Gravity plays a major part so ensure slopes

run the correct way. It really isn't rocket

science but you will get caught out if you

choose to ignore the simple

principles. |